Manure spreaders / muck spreaders agricultural trailers Juscafresa.

Destined for large corporations or agriculture works / farms.

Stands out for its excellent spread quality, its extreme strongness and high load capacity superior from the other series for agricultural corporations requiring to mount the bodywork on a truck chassis with an assembled spreader that provides the same quality that can be found in similar models made for tractor.

Standard equipped with:

Drag system 6 chains 80/18W 27 Mn Cr B5-2 + HARDOX 450

Double set of drag rungs by set of 6 chains for mud

Bodywork mounted on truck with spreader system of vertical beaters

Veritcal beaters of 2 columns chopping type group SP 1000/405 rpm with screwing flat spikes and height 2200 mm

Hydraulic back cover with vertical opening type guillotine with cylinder compensation system

Hydraulic back cover for beaters protection 2200 mm

Upper awning pneumatic or electric power up used by radio controler by cable with rails to protect the load

Capacity: according to truck

MODELS

E55TM2***002

16,85m3

E65TM2***002

20,19m3

E55TM2***002 | E65TM2***002 | |

|---|---|---|

m3 | 16,85 | 20,19 |

A | 9000 | 10000 |

B | 6410 | 7410 |

C | 2550 | 2550 |

E | 2300 | 2300 |

F | 1430 | 1430 |

G | 3030 | 3030 |

J | 3400 | 3400 |

U | 5500 | 6500 |

Descriptions, data and illustrations are only indicative. Juscafresa reserves the right to make any changes without prior notification.

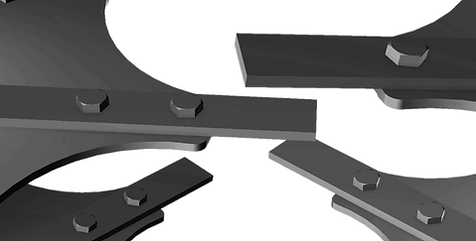

Spreader system

Veritcal beaters of 2 columns chopping type with screwing flat spikes.

Serial speed 1000/405rpm.

The lower plates are protected by plates in order to avoid the material fall directly to the floor and ensuring it is spread through the back without falling below the machine and getting it dirty.

Symetrical star shape of Beaters and serial screwing flat spikes.

Serial speed 1000/405rpm.

Spikes

Screwing flat spikes for serial beaters.

Material steel or stainless

4mm side thickness and 4mm floor thickness.

Floor, laterals, hydrauilc back cover and frontal stainless optional.

Drag system

Kit of 6 chains 80/18W manufactured with material 27 Mn Cr B5-2 + Hardox 450.

Hydraulic use for the chains and the beaters.

Double set of drag rungs by set of 6 chains for mud.

Double lower bottom chains.

Reducer

Hydraulic advance chains with double reducer 1/12,1 used from the cabin.

Velocity commandment from the chains

Electronic velocity commandment from the chains floor of standard.

Cover

Hydraulic back cover with vertical opening type guillotine with cylinders compensation system.

The vertical opening type guillotine can add an indicator door opening for hydraulic back cover.

More options

DRAG SYSTEM

Spreader group of 2 plates for mud

BOX AND SPREADER GROUP

Tool box.

Water tank.

Semicircular polyethylene mud guard independent for every wheel.

“A higher quality finish means more machine life”

The Juscafresa finishing process is:

-Polishing of the whole machine removing the impurities that persist in the metal.

-Pressurized washing with degreaser solution to obtain a better grip on the primer and prevent corrosion.

-Wash at high pressure with hot water to remove dirt from the metal and remains of adhered products.

-Application of a high quality primer layer.

-Application of two layers of Juscafresa paint specially designed with our corporate color.

Descriptions, data and illustrations are only indicative. Juscafresa reserves the right to make any changes without prior notification.